Home > Products > stainless steel flange > Pressure vessel ASME neck flat welding SA182F304 stainless steel flange American standard forging

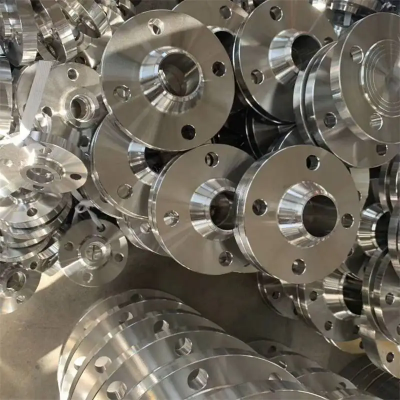

Pressure vessel ASME neck flat welding SA182F304 stainless steel flange American standard forging

- China

- T/T L/C

- 7 days

You May Like

-

Metallurgical Building ASME Large Diameter High Neck SA182F347H Stainless Steel Flange American Standard Shaped Forging

-

Pressure vessel ASME plate flat welding SA182F316 stainless steel flange American standard forged cake

-

Metallurgical construction ASME flanged ring plate SA182F316L stainless steel flange American standard forging

-

ASME/AST American standard A182F11 flange F12 customized P22 eccentric reducer

-

Metallurgical construction ASME neck flat welding SA182F347H stainless steel flange American standard forging

-

ASME flat welding ring loose sleeve SA182F904L stainless steel flange American standard forged for power engineering

Product Details

| Manufacturing Way | Forging | Connection | Flanged | |

| Structure | Round | Material | Stainless Steel | |

| Type | Other, Stainless Steel Flange |

Product Description

Product Overview

Our Pressure vessel ASME neck flat welding SA182F304 stainless steel flange is a high - quality product designed to meet the strict requirements of various industrial applications. This flange is forged, which gives it superior strength and durability compared to other manufacturing methods. It adheres to the American standard, making it suitable for use in international projects where compliance with ASME standards is crucial.

Manufacturing and Material

- Manufacturing Way: Forging Forging is a manufacturing process that involves shaping metal by applying compressive forces. This method results in a flange with a dense and uniform grain structure. The forging process enhances the mechanical properties of the flange, such as its tensile strength, toughness, and resistance to fatigue. It can withstand high - pressure and high - temperature environments, making it ideal for use in pressure vessels.

- Material: SA182F304 Stainless Steel SA182F304 stainless steel is a widely used austenitic stainless steel. It contains chromium and nickel, which provide excellent corrosion resistance. This material is resistant to a variety of corrosive substances, including acids, alkalis, and salts. It also has good oxidation resistance at high temperatures, ensuring the long - term performance of the flange in harsh industrial environments.

Structural Features

- Structure: Round The round structure of the flange is a classic and practical design. It provides a uniform distribution of stress around the circumference, which is essential for maintaining the integrity of the connection. The round shape also allows for easy installation and alignment with other components in the system.

- Neck Flat Welding Design The neck flat welding design of this flange offers several advantages. The neck provides additional reinforcement, increasing the strength of the joint. Flat welding is a reliable and commonly used welding method that ensures a strong and leak - proof connection between the flange and the pipe. It is suitable for applications where the pressure is relatively low to medium, and it is easy to perform on - site welding.

Connection Type

- Connection: Flanged The flanged connection is a popular choice in industrial piping systems. It allows for easy installation, disassembly, and maintenance. The flange can be bolted to another flange or a mating component, creating a tight and secure connection. This type of connection also provides flexibility in the system, as it can accommodate some degree of misalignment.

Application and Compatibility

- Pressure Vessel Applications This flange is specifically designed for use in pressure vessels. Pressure vessels are used in a wide range of industries, including chemical, oil and gas, power generation, and food processing. The high - quality materials and precise manufacturing of our flange ensure its reliability and safety in these critical applications.

- Compatibility with American Standards As it adheres to the American standard (ASME), this flange is compatible with other components that follow the same standard. This makes it easy to integrate into existing systems or new projects in North America and other regions where American standards are commonly used. It also simplifies the procurement process, as customers can be confident that the flange will meet the required specifications.

Quality Assurance and Company Background

Our company, established in 2017, is a professional manufacturer of stainless steel products. We have a team of 11 - 20 experienced sales representatives who are dedicated to providing excellent customer service. With an annual export share ranging from US$5 Million to US$10 Million, we have a proven track record in the international market. Our products are sold in various regions, including North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, as well as the domestic market.

We adhere to strict quality control measures throughout the manufacturing process. Each flange undergoes rigorous testing to ensure it meets the required standards for dimensions, material properties, and performance. Our commitment to quality and innovation has earned us a good reputation among our customers worldwide.

Whether you are looking for a reliable flange for a new pressure vessel project or need to replace an existing flange, our Pressure vessel ASME neck flat welding SA182F304 stainless steel flange is an excellent choice. Its high - quality materials, superior manufacturing process, and compliance with international standards make it a product that you can trust.

Company Profile

Wuxi Weiman Gaodeng Special Steel Co., Ltd. About Us Founded in 2017, Wuxi Weiman Gaodeng Special Steel Co., Ltd. is a leading supplier of high-quality special steel products, specializing in stainless steel, alloy steel pipes, nickel-based alloys, high-temperature alloys, and titanium alloys. Located in Wuxi City, Jiangsu Province, China, our company leverages its strategic position to serve customers globally, combining advanced manufacturing capabilities with a commitment to innovation and reliability. Product Range - Stainless Steel: We offer a wide range of stainless steel products known for their corrosion resistance, durability, and versatility, suitable for applications in chemical processing, food industry, and architectural projects. - Alloy Steel Pipes: Our alloy steel pipes are designed for high-strength and high-temperature environments, widely used in power generation, oil & gas, and machinery manufacturing. - Nickel-Based Alloys: These alloys excel in extreme conditions, providing exceptional resistance to corrosion, oxidation, and high temperatures. They are critical for aerospace components, marine equipment, and petrochemical systems . - High-Temperature Alloys: Engineered to maintain stability at elevated temperatures, these alloys are ideal for gas turbines, heat exchangers, and aerospace propulsion systems . - Titanium Alloys: Lightweight yet robust, our titanium alloys are used in medical implants, aerospace structures, and sports equipment due to their superior strength-to-weight ratio and biocompatibility. Core Strengths 1.?Global Partnerships: We collaborate with renowned domestic and international manufacturers, including Baowu Steel, Nippon Steel, and ThyssenKrupp, ensuring access to premium raw materials and advanced production technologies . 2.?Quality Assurance: Our products comply with strict international standards (e.g., ASME, ASTM, DIN, EN, and GB) and undergo rigorous testing to guarantee performance and safety . 3.?Customization: With a large inventory and flexible production capabilities, we provide tailored solutions to meet unique project requirements, including special dimensions and material specifications . 4.?Industry Expertise: Serving industries such as oil & gas, power generation, aerospace, and automotive, we deliver materials that withstand the most demanding operational conditions . Commitment to Excellence At Wuxi Weiman Gaodeng, we prioritize customer satisfaction through timely delivery, technical support, and continuous improvement. Our state-of-the-art facilities and experienced team enable us to consistently exceed expectations, positioning us as a trusted partner for global clients. Vision To become a world-leading provider of special steel solutions, driving innovation and sustainability in key industries worldwide.

Contact Us

- Wuxi Weiman Gaodeng Special Steel Co., Ltd.

- Contact nameSang Le Chat Now

- AddressNo. 168 Qiangao Road, Wuxi, Jiangsu

Product Categories

| Titanium Alloy | Nickel Based Alloy | Stainless steel pipe | Aluminum Alloy |

| Stainless steel round bar | stainless steel plate | stainless steel flange |

New Products

-

Forged forging A335P91 flange DN200 PN16 pressure surface intact

-

ASME Neck Welding Ring Loose Set SA182F304 Stainless Steel Flange American Forged Ring for Power Engineering

-

The surface of the A182F12 flange F91 diagonal tee of the takeover seat pipeline is intact

-

Complete specifications A182F22 flange 15NiCuMoNb5-6-4 elbow production factory

-

12cr1mov flange F11 grade HG/T20592 for petrochemical pipelines

-

1Cr5Mo flange corrosion-resistant high-temperature production plant for petrochemical pipelines

-

ASME/AST American standard A182F22 flange 15NiCuMoNb5-6-4 elbow GB/T12459

-

Connecting pipeline with ASME neck butt welding ring loose sleeve SA182F316 stainless steel flange American standard forged pipe

-

Gr1 Titanium Bars (Commercial Pure) – High Corrosion Resistance, Annealed/Hot Rolled – Factory Direct Supply

-

Gr2 Pure Titanium Rods – ASTM B348 Certified, Excellent Formability – Custom Cut to Length, Quick Delivery

-

Gr5 Titanium Alloy Bars (Ti-6Al-4V) – Aerospace-Grade Strength, Heat Treated – AMS 4928 Compliant, In-Stock

-

Gr7 Titanium-Palladium Bars (Ti-Pd Alloy) – Superior Corrosion Resistance in Sea Water/Chemicals – Mill Finish or Polished

-

Gr12 Low-Alloy Titanium Bars – High Temperature Stability (≤500°C), Weldable – For Heat Exchangers & Petrochemical Equipment

-

Titanium Grade 1 Plate - ASTM B265 Certified, Mill Finish, Custom Cut to Size

-

Titanium Grade 2 Plate - Annealed Condition, ISO 9001:2015 Certified, Ready to Ship

-

Titanium Grade 5 Plate (Ti-6Al-4V) - High Strength, Aerospace Grade, CNC Machining Available

-

Titanium Grade 7 Plate (Ti-Pd Alloy) - Corrosion Resistant, Medical-Grade, Polished Surface

-

Titanium Grade 12 Plate (Ti-0.3Mo-0.8Ni) - Excellent Weldability, Industrial Grade, Mill Test Certificates

-

ASTM B164 Certified Monel 400 Round Bar | Corrosion-Resistant Nickel-Copper Alloy Bar Stock

-

ASME B865 Compliant N05500 Bar Stock | Marine-Grade Corrosion-Resistant Monel K-500 Alloy Bars

-

ASTM B166 Compliant Inconel 600 Bar Stock | High-Temperature & Oxidation-Resistant Nickel-Chromium Bars

-

ASME SB-166 Certified N06600 Round Bar | Heat-Resistant Inconel 600 Alloy Bars for Industrial Use

-

ASTM B446 Compliant Inconel 625 Superalloy Bar | High-Strength Corrosion-Resistant Bar Stock

-

ASME SB-446 Certified N06625 Round Bar | Weldable High-Performance Inconel 625 Alloy Bars

Popular Searches

- pipe fitting

- machinery part

- stainless steel

- stainless steel flange

- carbon steel flange

- steel flange

- Blind Flange

- Slipon Flange

- Weld Neck Flange

- Pipe Flange

- Welding Neck Flange

- Plate Flange

- Threaded Flange

- Forging Flange

- Forging Part

- steel forging

- shaft forging

- forged block

- forged pipe

- flange plate

- Steel Forged Flange

- Carbon Steel Forged Flange

- forged piston

- Forged Blind Flange

- pipe fitting

- aluminum parts

- stainless steel

- hose fitting

- stainless steel flange

- steel flange

Find Similar Products By Category

- Industrial Equipment & Components > Fastener & Fitting > Flange

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Sang Le

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile